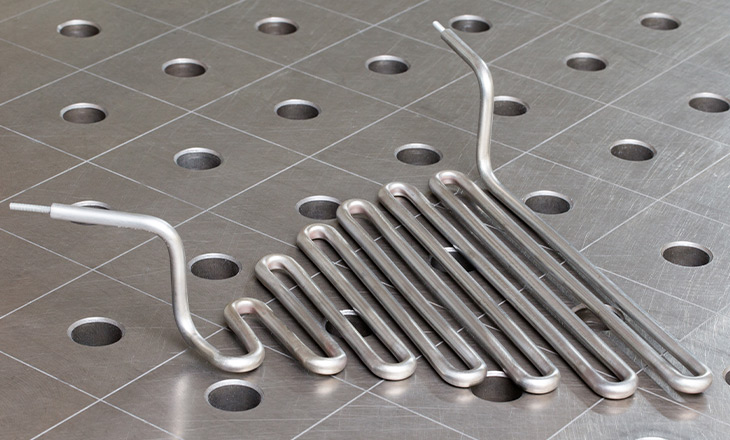

SRHK tubular heater

SRHK tubular heaters are electrical resistors that have been tried and tested for decades and convert electrical energy into heat with virtually no losses. The actual resistor consists of a heating coil surrounded by heavily compressed magnesium oxide (MgO) and centered in a VA tube. MgO is used to insulate the heating coil from the outer tube and has excellent thermal conductivity. Tubular heaters are bendable and thus easily adaptable to individual process conditions.

Wide range in terms of design and pipe material

Seal technology guarantees first-class insulation resistance > 1 Terra Ohm

High quality MgO for high electrical safety and excellent thermal conductivity

Production according to DIN 44.874 and VDE 0720

Application areas of tubular heaters

- Tool heating

- Industrial furnace construction

- Mechanical and plant engineering

- Miscellaneous

Structure and material

Tubular heaters are made of VA steel alloys (1.4404, 1.4571, 1.4828, 1.4876, 2.4858). The heating coil centered in the tube is embedded in highly compressed magnesium oxide powder. This component electrically insulates the heating wire from the outer tube and has high thermal conductivity. Diameters of 6.5, 8.5, 10.0, 11.5, 16.0 mm and stretched lengths ≤ 7000 mm are possible. Depending on the temperature level, the heater is sealed with silicone or a 2-component casting resin, which in this case guarantees a durably high insulation resistance of > 1 Tera Ohm.

Siekerkotte supplies the desired shape starting from batch sizes of 1: U-shape, W-shape in any number of sheets, meandering, double helix on one or more levels, double or multiple folded over and other special shapes on request. Various connection options are also available: By thread, plain pin, flat pin, stranded wire, etc.

The surface area of tubular heaters can be increased by applying a stainless steel coil to reduce surface stress. Finned tube heaters are available upon request. Production according to DIN 44.878 and VDE 0702 guarantees a constant quality.

Siekerkotte supplies the desired shape starting from batch sizes of 1: U-shape, W-shape in any number of sheets, meandering, double helix on one or more levels, double or multiple folded over and other special shapes on request. Various connection options are also available: By thread, plain pin, flat pin, stranded wire, etc.

The surface area of tubular heaters can be increased by applying a stainless steel coil to reduce surface stress. Finned tube heaters are available upon request. Production according to DIN 44.878 and VDE 0702 guarantees a constant quality.

Technical data

Tubular heater

Diameter

6.5 mm; 8.5 mm; 10.0 mm; 11.5 mm; 16 mm

Material

1.4404; 1.4571; 1.4828; 1.4876; 2.4858 (others on request)

Length stretched (Lg)

Total length of the tubular heater: max. 7m

Unheated length

By agreement

Inner diameter (D1)

Standard: 20mm for 8.5 RHK, 23.5mm for 11.5 RHK, 24mm for 16 RHK or by agreement

Center-to-center distance (M)

Center-to-center distance between connecting bolts. (D+D1)

Connection

By thread; plain pin; flat pin; stranded wire

Fastening nipple

Standard: M14 x 1.5 or by agreement

Let’s talk about it!

No electric heating solution is exactly like the other! Let us advise you on what your optimal heating solution looks like.

Write an email